LIT SENG uses quality and efficient thermoforming technologies to turn your concept into premium plastic packaging! Our primary focus is on design, manufacturing, quality assurance, and mould testing in order to assist our customers who are manufacturers or brand owners. We combine these parts into a full-service package that not only delivers what you need but also assists you in building premium quality thermoforming moulds that produce huge volumes of food packaging. LIT SENG designs and manufactures high quality thermoforming and vacuum-forming moulds for a wide range of industrial applications. With over 27 years of experience and a solid reputation for excellent thermoforming tooling and customer care, we can customize thermoforming moulds to match your machines and food packaging demands. Whatever your needs are, LIT SENG has the unique tooling experience and professional knowledge to assist you in finding the ideal thermoformed food package solution.

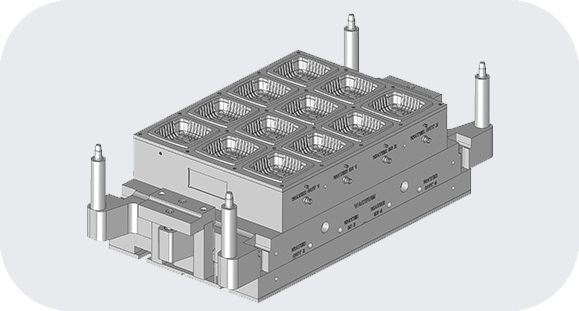

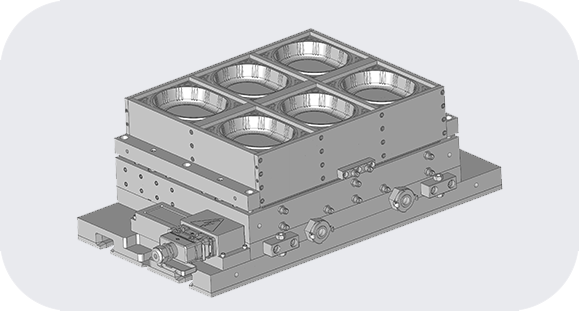

BFS Mould

BFS Mould, which form and cut in the same station, are mostly used to produce thermoformed Container or goods that require exceptional consistency in their cutting edge.

Product Category

Tray

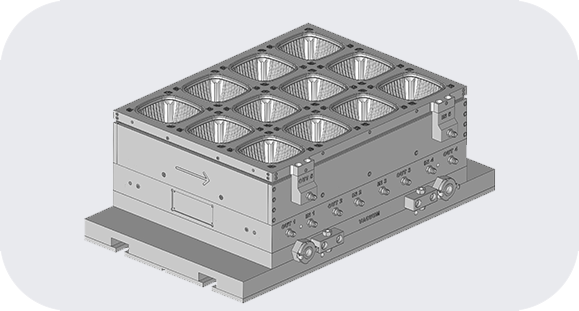

3 Station Mould

3 station – Pressure forming mould – steel rule cutter – in-line stacking, suitable for produce meal tray and clamshell lunch box can reach high productivity and quality. This style tooling can run flexible product and frequently mould changing.

Product Category

Lids

Containers

Eggs Tray

OPS Clamshell

Multi Lunch Box

Tray

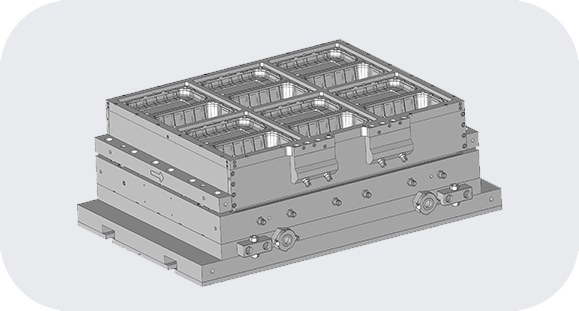

4 Station Mould

Pressure forming mould – steel rule cutter – in-line stacking plus additional in-line hole punching press to process tray with holes punch or sidewall punch. For example in Strawberry clamshell tray, Coffee lid or Berry tray.

Product Category

Lids

Fruit Clamshell

C-PET

Thermoformed parts with temperature resistance in oven up to ~220°C.